Mastering CNC Machining: Tips for Success in California

In the intricate world of precision manufacturing, CNC machining stands out as a revolutionary process that has redefined the way components are fabricated. Whether you’re a seasoned professional or a novice launching into the realm of CNC machining in California, the key to success lies in mastering the techniques that can unlock the full potential of this technology.

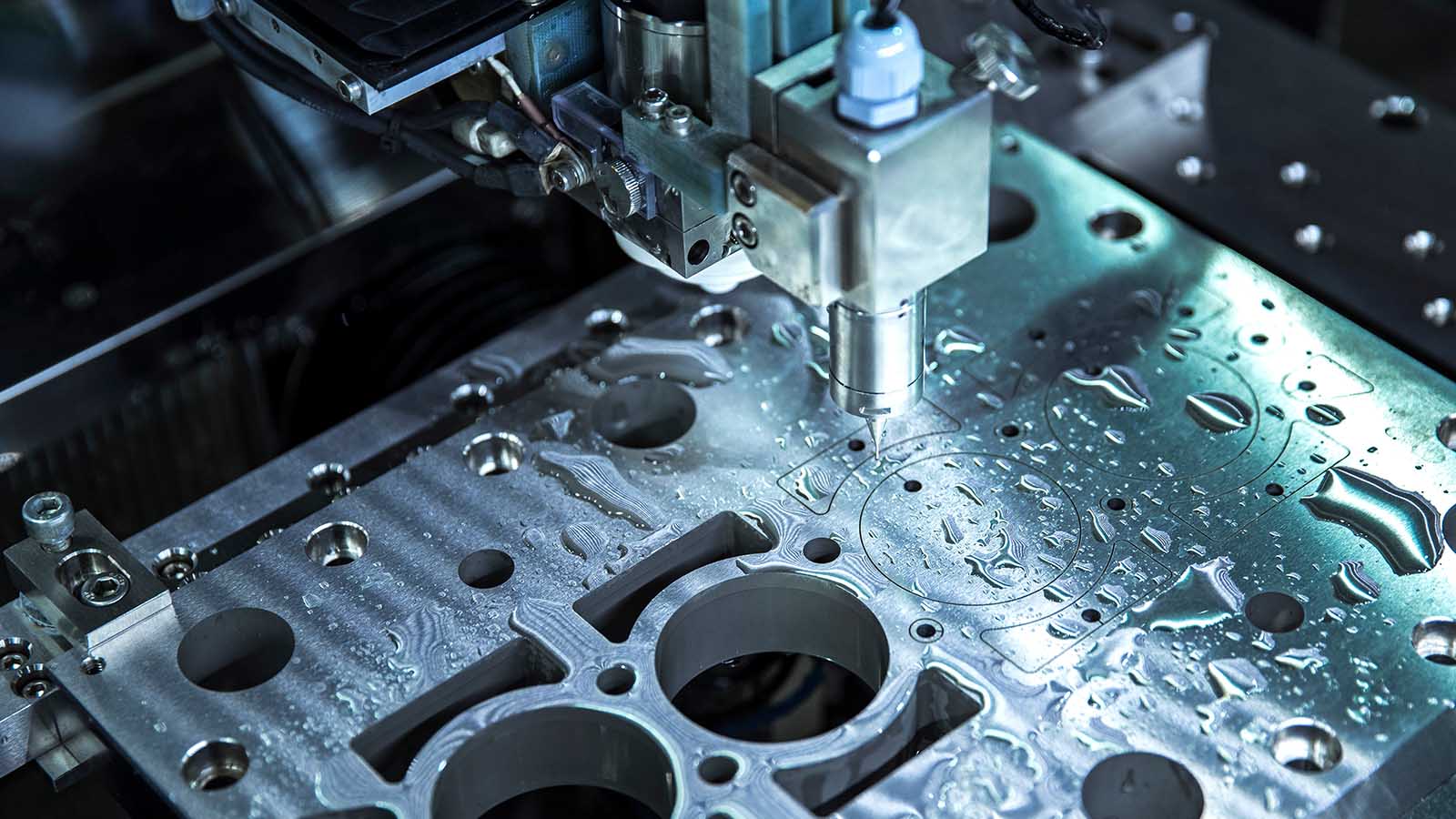

The Essence of CNC Machining

CNC machining, short for computer numerical control machining, is a sophisticated method that employs computerized systems to control the movement of machining tools. This precise and automated approach ensures unparalleled accuracy in the manufacturing process. In California, where innovation is paramount, CNC machining has become a cornerstone in various industries, ranging from aerospace to medical device manufacturing.

Navigating the CNC Landscape

To truly master CNC machining, one must first familiarize themselves with the basics of the technology. Understanding the intricacies of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) is essential. These tools empower manufacturers to create intricate designs and convert them into a language that CNC machines comprehend. The integration of CAD and CAM software is the backbone of successful CNC machining projects in California and beyond.

Precision Matters: Optimizing CNC Programming

The heart of CNC machining lies in programming. The instructions provided to the CNC machine dictate the entire manufacturing process. California-based manufacturers looking to excel in CNC machining must prioritize optimizing programming techniques. Fine-tuning speed, feed rates, and toolpath strategies can significantly impact the quality of the final product. CNC machining, when mastered, allows for the production of intricate components with minimal waste and maximum efficiency.

Choosing the Right Materials

California, a hub of innovation, demands CNC machining that can handle a diverse range of materials. Mastering CNC machining involves a deep understanding of the materials being worked with. Whether it’s aluminum, titanium, or exotic alloys, selecting the right cutting tools and parameters is crucial. CNC machining, when tailored to the specific material properties, ensures durability and precision in the final product.

Quality Control: A Non-Negotiable Aspect

Mastering CNC machining in California requires a commitment to quality control. Rigorous inspection processes, including the use of advanced metrology tools, are essential to ensure that every component meets the specified tolerances. California-based manufacturers must prioritize quality to meet the stringent standards prevalent in industries such as aerospace and medical manufacturing.

Embracing Continuous Learning

In the dynamic landscape of CNC machining, staying updated on the latest advancements is key to success. California’s competitive manufacturing sector demands a commitment to continuous learning and adaptation. Whether it’s attending workshops, participating in industry forums, or investing in employee training, staying ahead of the curve is paramount.

Collaborative Partnerships and Networking

Success in CNC machining in California is often a collaborative effort. Building strong partnerships within the manufacturing community can lead to shared knowledge and opportunities for growth. Networking with industry experts, suppliers, and other CNC machining professionals can provide valuable insights and open doors to new possibilities.

Preece Machining and Assembly: Your Partner in Success

Amidst the vast landscape of CNC machining services in California, one company stands out Preece Machining and Assembly. With a reputation built on years of excellence, Preece Machining is a go-to partner for businesses seeking top-notch CNC machining solutions. Our state-of-the-art facility in California is equipped with cutting-edge CNC machines operated by skilled technicians, ensuring precision and quality in every project.