The start of a project always begins the same: Request for a quote, or RFQ. Once a RFQ is received, our custom quoting software allows us to analyze the geometry and highlight possible problematic features. Our team is instantly notified of the pending RFQ and the process is started. One powerful feature of our quoting software is the ability to easily quote many different quantities of the same part for our customers to demonstrate price saving opportunities.

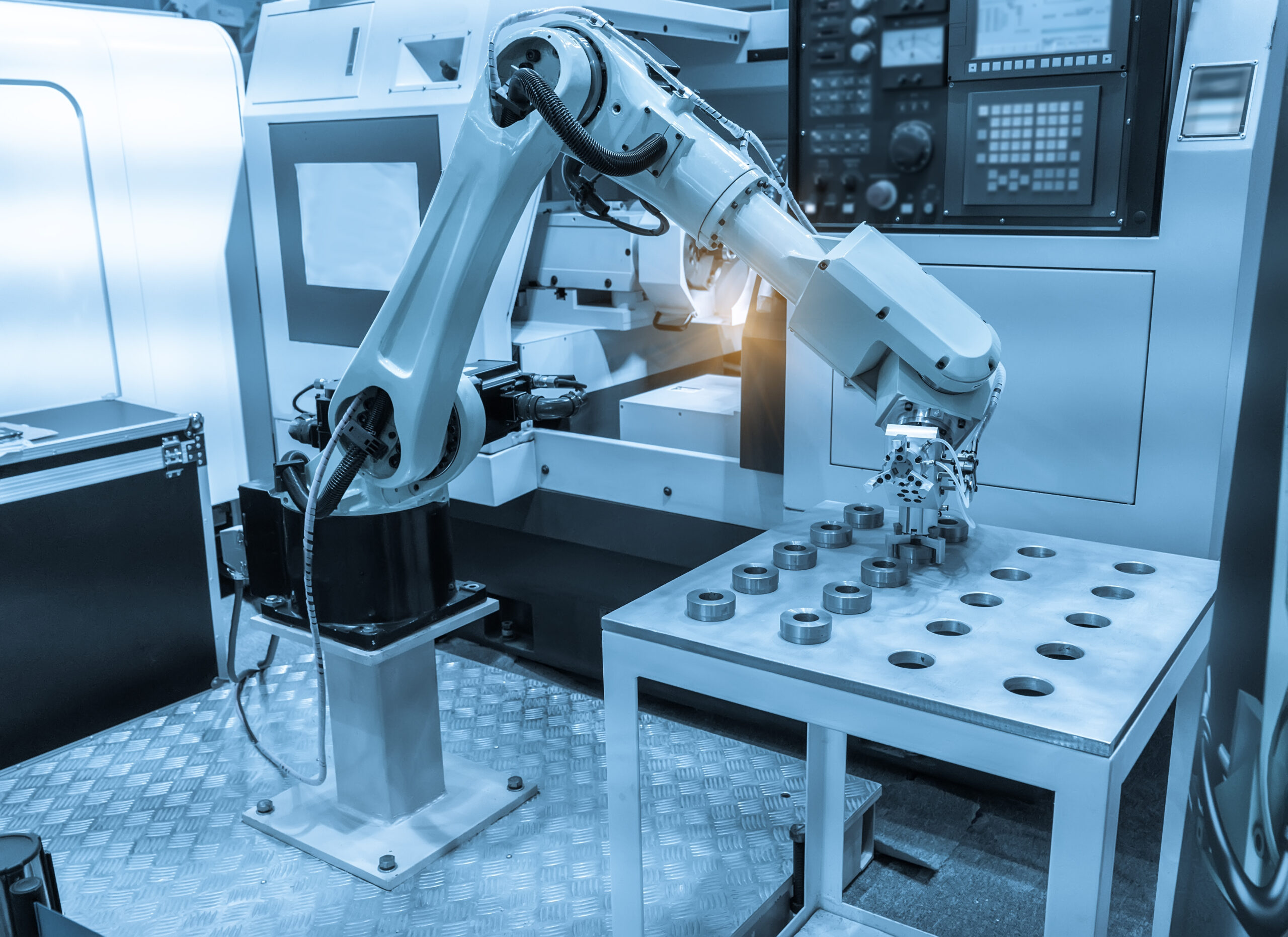

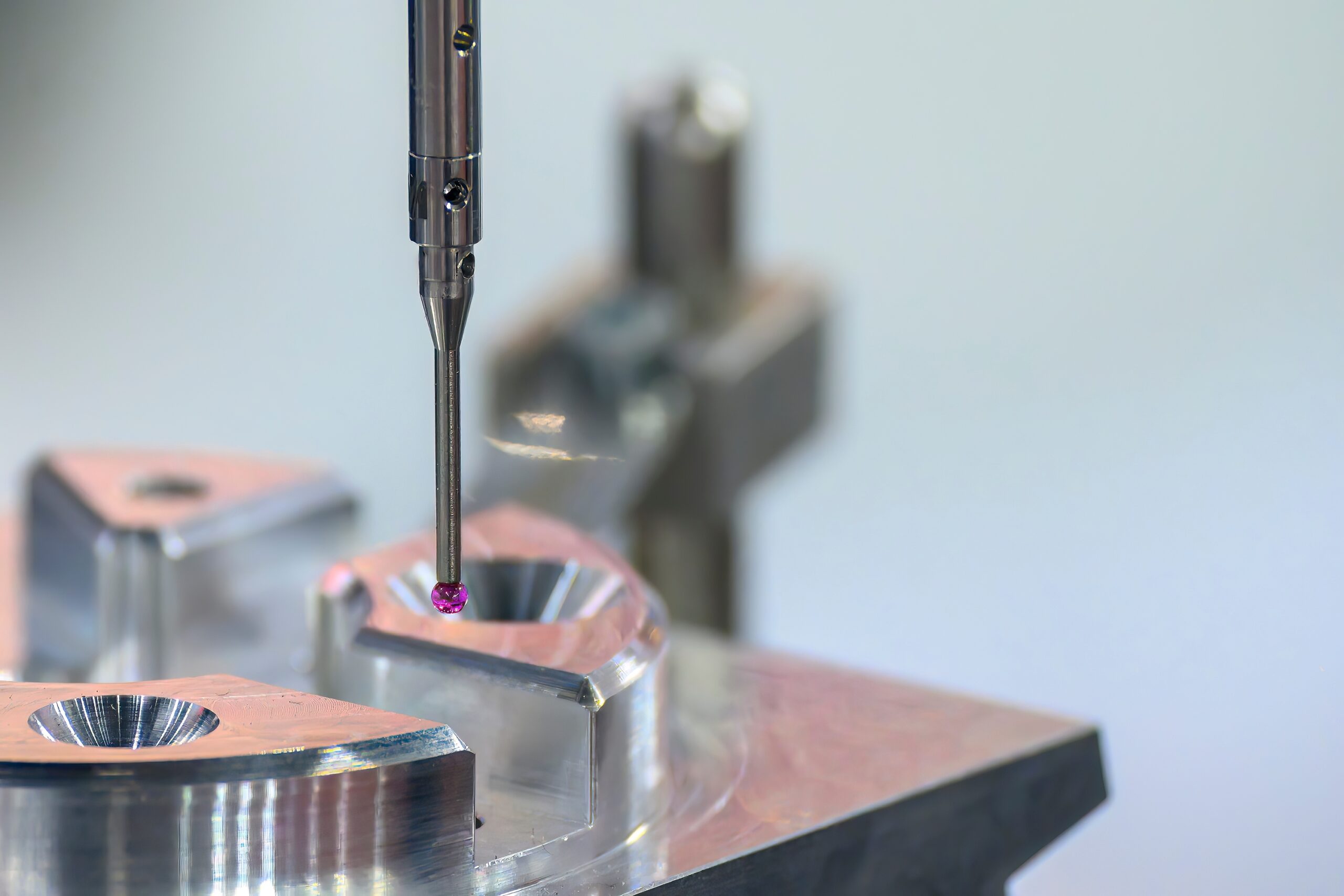

The most significant expenses associated with high volume CNC machining are machining time, set-up costs, material costs, and inspection. As the volume of a project increases, the more time can be allocated towards increasing the efficiency of every aspect of part production. Each area of the project that can be optimized results in savings passed along to our customers. We are able to pin point these areas consistently with our dedicated, highly skilled team of machinist and project managers.