QUALITY ASSURANCE

Our Inspection Capabilities

When you work with Preece Machining and Assembly, you can trust that only the highest quality of parts will be delivered.

Equipped with our highly esteemed inspection machines and the technical experience to create the most complicated of parts, we work tirelessly to ensure that each and every custom part that leaves our shop meets our company and industry standards.

Vetted For Highest Quality

We take pride in the quality of products that we distribute. This is why we've pursued and acquired our AS9100:2016 & ISO 9001:2015 certification and offer First Article Inspection reports upon request.

What you can expect from our FAI:

- Full traceability to NIST standards (thread gages, pins, gage blocks, and hand tools)

- Material traceability. We catalog all of our incoming material and store material certifications for a minimum of 5 years unless otherwise requested by a customer.

- DFARS compliant material is also available

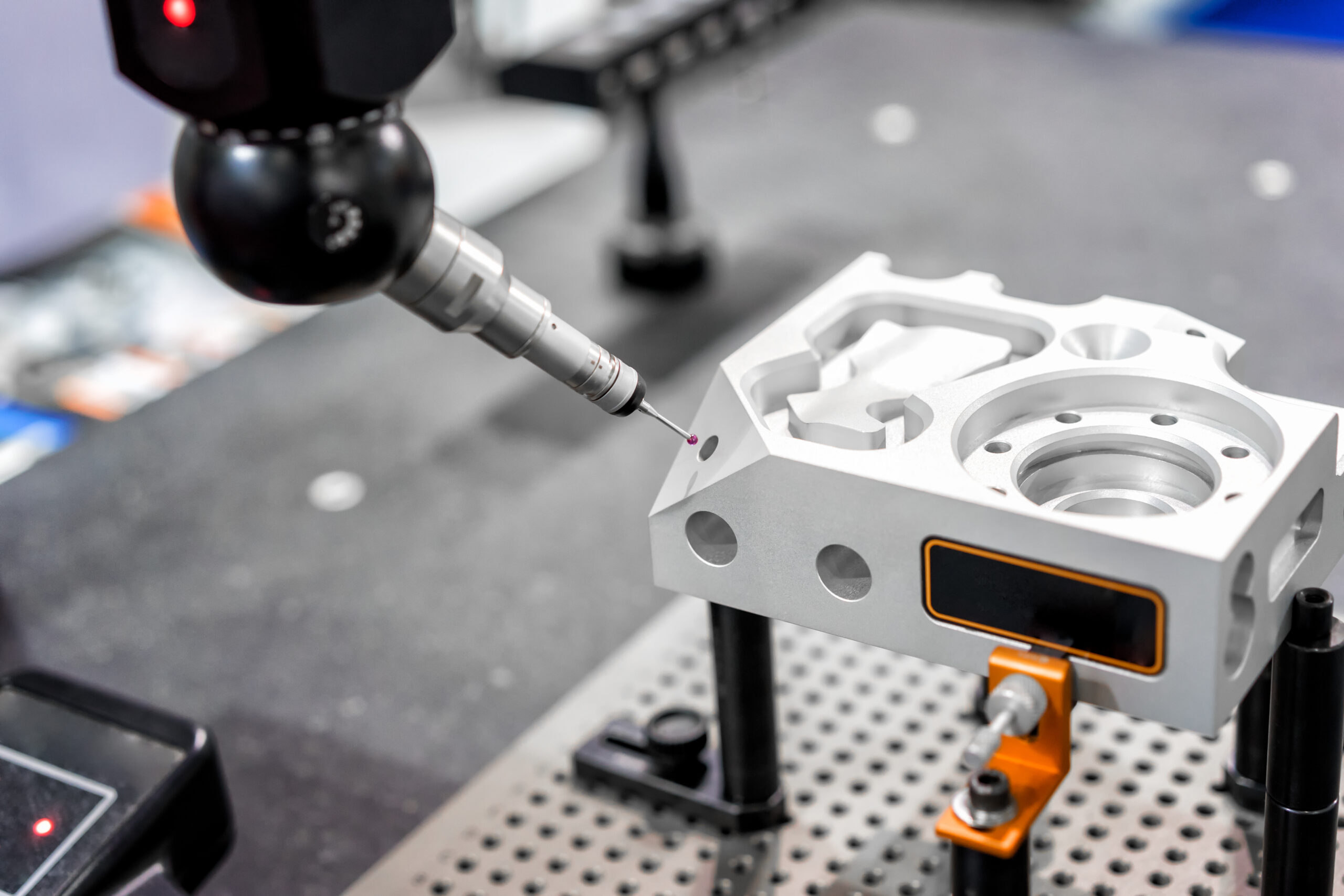

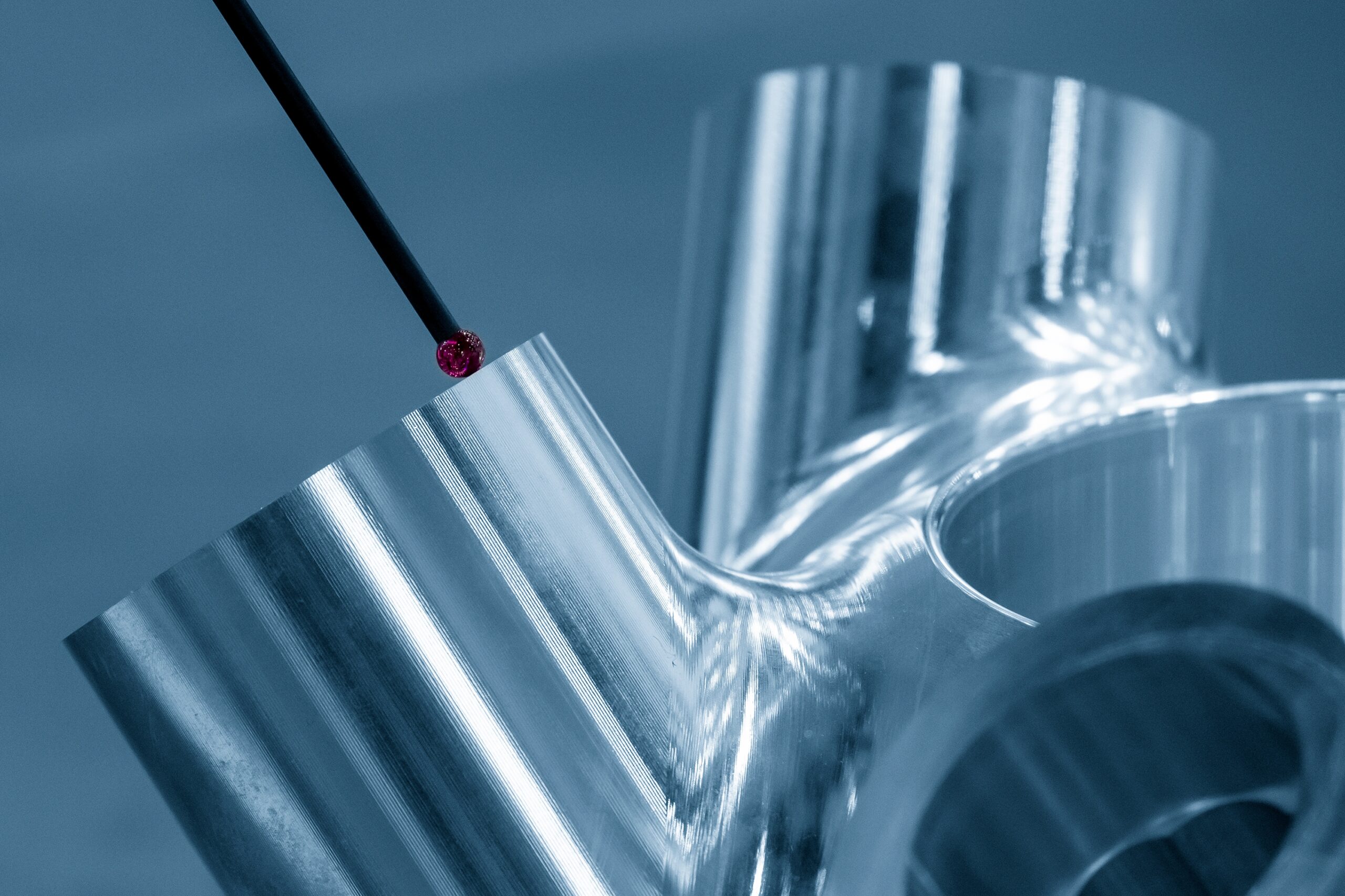

All about our CMM

Our Mitutoyo Crysta Apex V Series is fully equipped with a Renishaw PH10MQ articulating head to reach tight or difficult to reach areas. Our CMM also has full scanning capabilities. Scanning in terms of a CMM is when the ruby (stylus) is moved across a part or feature with the ruby in constant contact with the part. This allows us to create a point cloud of data points and ultimately more accurate measurements.

- Measuring range: 19.6 x 27.5 x 15 (500mm x 700mm x 400mm)

- Max. Permissible Length Measurement Error (ISO 10360-2: 2009)*2 : (1.7 + 3.0L/1000)μm

- Equipped with the latest version of MCOSMOS and MICAT PLANNER

Powerful ERP

PMA is proudly powered by ProShop! Having a ERP that ties our quality manual into day to day operations ensures our customers receive the highest quality parts on time, every time. From data collection and purchasing to scheduling and quality; ProShop provides the consistency we need to deliver an unparalleled customer experience. Quality is at the heart of Preece Machining & Assembly and quality is the language of our ERP.

- Fully integrated quality manual

- Complete visibility from RFQ to First article and shipping

- AS9100D quality manual

1Factory

1 Factory lets Preece Machining & Assembly automate a traditionally manual aspect of the CNC manufacturing process. The ability to keep inspection cost down by leveraging technology lets PMA pass the saving on to our customers. 1 Factory reduces the risk of operator error when building out inspection plans by auto bubbling prints for FAI’s, tracking revision history, detecting trends in the manufacturing process, and logging incoming material and part inspections. Dedication to inspecting every part is costly, automating the process lets PMA remain competitive and agile.

- Automatic Ballooning

- Quality Control Plans

- Automated CMM Data Import

- Defect Risk Detection

Let’s Talk Inspection

Give us a call. One of our QA experts will be happy to discuss your project. Whether you need GD&T input or have a question about the manufacturing process; one of our QA specialists can help.

We are here for you.

- Full access to our GD&T experts

- Request access to our QMS

- Request Inspection Quote