Why Our Aerospace Shop Might Be The Best Option For Your High Volume Project

Aerospace Machine Shops Just Cost More

For some reason, most commercial customers we talk to with high volume machining projects assume an aerospace machine shop like Preece Machining & Assembly wouldn’t be a good fit. I believe this comes from the idea that aerospace machine shops flat out cost more, and this is not totally untrue. Speaking from our experience as we are currently ISO9001:2015 certified and amid our AS9100D audit, we can say that the cost of maintaining a robust QMS, auditing that QMS, and regularly calibrating metrology equipment absolutely are expenses that a non-aerospace machine shop simply does not need to worry about. This does not even take into consideration all the peripheral expenses that help us manage an aerospace machine shop like a powerful ERP or even the added cost of diligently tracking every piece of material. But I would argue that our requirement to document everything and our commitment to continuous improvement means we produce the same result faster and more efficiently than a shop that doesn’t embody these principles.

Tooling Experts

Our CNC machine shop located in Boulder, Colorado has had the opportunity to undertake many complex aerospace projects as well as production jobs. One common element is the requirement to have tooling know-how. On a regular basis we must order or in some cases design custom tooling to get the job done. In the aerospace world this is usually required to make one feature and not so much to shave a few moments off a cycle time. But, in the production world, there are many instances where we need to design a custom tool to remain competitive with cycle time. One example that comes to mind is a custom form tool we designed that machines two profiles as well as a chamfer in one pass. This tool allowed us to remove 3 tools and replace them with 1 tool. This might not sound like a big deal but with quantities in the thousands, a 3-4 second tool change adds up quickly. We have the technical tooling experience from years of CNC machining in the aerospace industry and have brought those same principles over to production.

Material experts

We take pride in the fact that our aerospace machine shop has mastered many different materials and has painstakingly documented the unique aspects of each one. This is a result of working on many challenging projects in the aerospace world; often not production runs, but this experience directly transfers. We have had the opportunity to work with many difficult materials like titanium, invar and stainless. This experience and documented knowledge of challenging material means we can push our tools harder and get projects up and running faster.

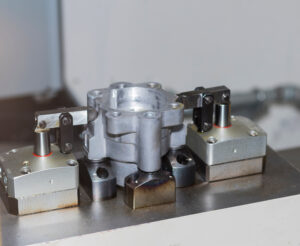

My Parts Require Fixturing

I have also heard in the past that “we need a shop with skill at designing fixtures because that’s the only way to produce these parts efficiently”, almost implying that aerospace machine shops don’t have as much familiarity with fixturing as production houses. This is simply not true. Our aerospace machine shop located in Boulder, CO specializes in what we call low volume production. Almost every part we make requires at least 1 fixture even if we are just making 1 part. This means every single CNC programmer here is a fixturing expert! Designing and implementing fixtures is at the core of what we do as an aerospace machine shop. This translates well to the commercial production world and provides areas of savings for our customers. Namely in NRE or non-recurring engineering fees. The more efficient at building fixtures we can be, the more savings we can pass along to our customers.

I have also heard in the past that “we need a shop with skill at designing fixtures because that’s the only way to produce these parts efficiently”, almost implying that aerospace machine shops don’t have as much familiarity with fixturing as production houses. This is simply not true. Our aerospace machine shop located in Boulder, CO specializes in what we call low volume production. Almost every part we make requires at least 1 fixture even if we are just making 1 part. This means every single CNC programmer here is a fixturing expert! Designing and implementing fixtures is at the core of what we do as an aerospace machine shop. This translates well to the commercial production world and provides areas of savings for our customers. Namely in NRE or non-recurring engineering fees. The more efficient at building fixtures we can be, the more savings we can pass along to our customers.

Management

I learned years ago that every dollar spent on technology to manage the shop gets paid back tenfold and provides a more seamless experience for my customers. We invested in a new ERP about a year ago and the level of detail our management team can provide to customers is incredible. Aspects of daily aerospace life like full material traceability and in-process inspection are easier than ever. Our team here has years of experience handling long term projects paired with our cutting-edge ERP; we have visibility into every job in real time. In addition to our ERP, we have real time machine monitoring and scheduling enabling a quoting feedback loop that ensures we quote every job for exactly how long it takes to produce.

Conclusion

Working with aerospace machine shops like Preece Machining & Assembly you get many benefits like tooling and fixturing experts. You get top notch job management, material traceability and world class technology powering your project. In our opinion the benefits of working with an aerospace shop for your high volume project are numerous. If you have a high volume commercial project you would like to get a quote on click here Get a Quote.