Posts by Nick Preece

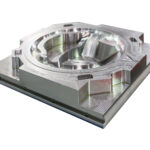

Why Our Aerospace Shop Might Be The Best Option For Your High Volume Project

Aerospace Machine Shops Just Cost More For some reason, most commercial customers we talk to with high volume machining projects assume an aerospace machine shop like Preece Machining & Assembly wouldn’t be a good fit. I believe this comes from the idea that aerospace machine shops flat out cost more, and this is not totally…

Read MoreLean Manufacturing in a Job shop

Lean Manufacturing and job shop are practically opposing philosophies. In a CNC precision job shop, standardization can be difficult and costly. At Preece Machining & Assembly we have been dedicated to finding a way to implement lean principles into our precision CNC job shop. What is a Job Shop? A job shop in this context…

Read MoreThreaded Insert Installation is a detailed process

Installation of threaded inserts, or Helicoils (popular brand name), is common in most machine shops – but your part could be exposed to risks if your shop isn’t doing it right. Preece Machining & Assembly on the other hand has many standard procedures to ensure your inserts are installed properly and your parts arrive as…

Read MoreLearning about CNC machining Invar 36, Super Invar 32-5 and Kovar

We love to grow with our customers from a business standpoint, but we really love to grow with them on new learning opportunities. During this last year Invar 36, super Invar, and Kovar have become standard material in our CNC milling department. We have grown to enjoy machining this material and would even go so…

Read More