Learning about CNC machining Invar 36, Super Invar 32-5 and Kovar

We love to grow with our customers from a business standpoint, but we really love to grow with them on new learning opportunities.

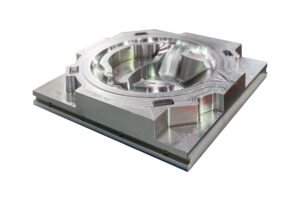

During this last year Invar 36, super Invar, and Kovar have become standard material in our CNC milling department. We have grown to enjoy machining this material and would even go so far to say we specialize in machining Invar. We have learned so much this last year and we would love to share it with you

Never heard of Invar?

Invar 36, Super Invar 32-5 and Kovar are known as controlled expansion and low expansion alloys. These alloys are made up of nickel, iron, and Kobalt in specific ratios to achieve a desired coefficient of thermal expansion. Kovar is a controlled expansion alloy and has very similar expansion characteristics to glass. Kovar is commonly used for glass to metal seals or when an application requires thermal expansion properties of glass and ceramics. Invar 36 and super Invar 32-5 are both consider low expansion alloys. Meaning over a temperature range the material grows or shrinks in size very little, especially when compared with steel. Invar is commonly used in the aerospace industry – even more now that carbon fiber had gained popularity. Invar is commonly used in carbon fiber molds due to its near zero expansion rate.

Difficulties surrounding Invar and CNC machining

Without question Invar 36, Super Invar 32-5 and Kovar would be classified as exotic alloys, both for their rareness and price. As a buyer you need a shop with experience machining these alloys and understands the challenges associated. At Preece Machining & Assembly we have been steadily honing our skills to produce highly complicated parts out of these materials. Invar 36 has a high cast iron content and is at risk for flash rusting. The solution is typically nickel plating. The nickel bonds well with the nickel in the alloy and produces a rust resistant coating. The challenge here is the threads cannot be left uncoated because they can rust or seize a bolt in the part. So, you need to over size the threads by a specific amount to ensure the thread profile is in spec after plating is complete. Here at Preece Machining & Assembly we have mastered the process for CNC machining Invar.

We love the opportunity to work with Invar and we think that is why we have become a reliable source for many of our customers invar needs. If you need a shop that knows the ins and outs of CNC machining controlled and low expansion alloys, get a quote form Preece Machining & Assembly.

1 Comment

Leave a Comment

You must be logged in to post a comment.

[…] transfers. We have had the opportunity to work with many difficult materials like titanium, invar and stainless. This experience and documented knowledge of challenging material means we can push […]