Preece’s CNC Machining: A Driving Force in Colorado’s Aerospace Industry

In this article, we will explore the pivotal role CNC machining plays in Colorado’s aerospace industry.

The CNC Machining Revolution: Powering Aerospace Advancements

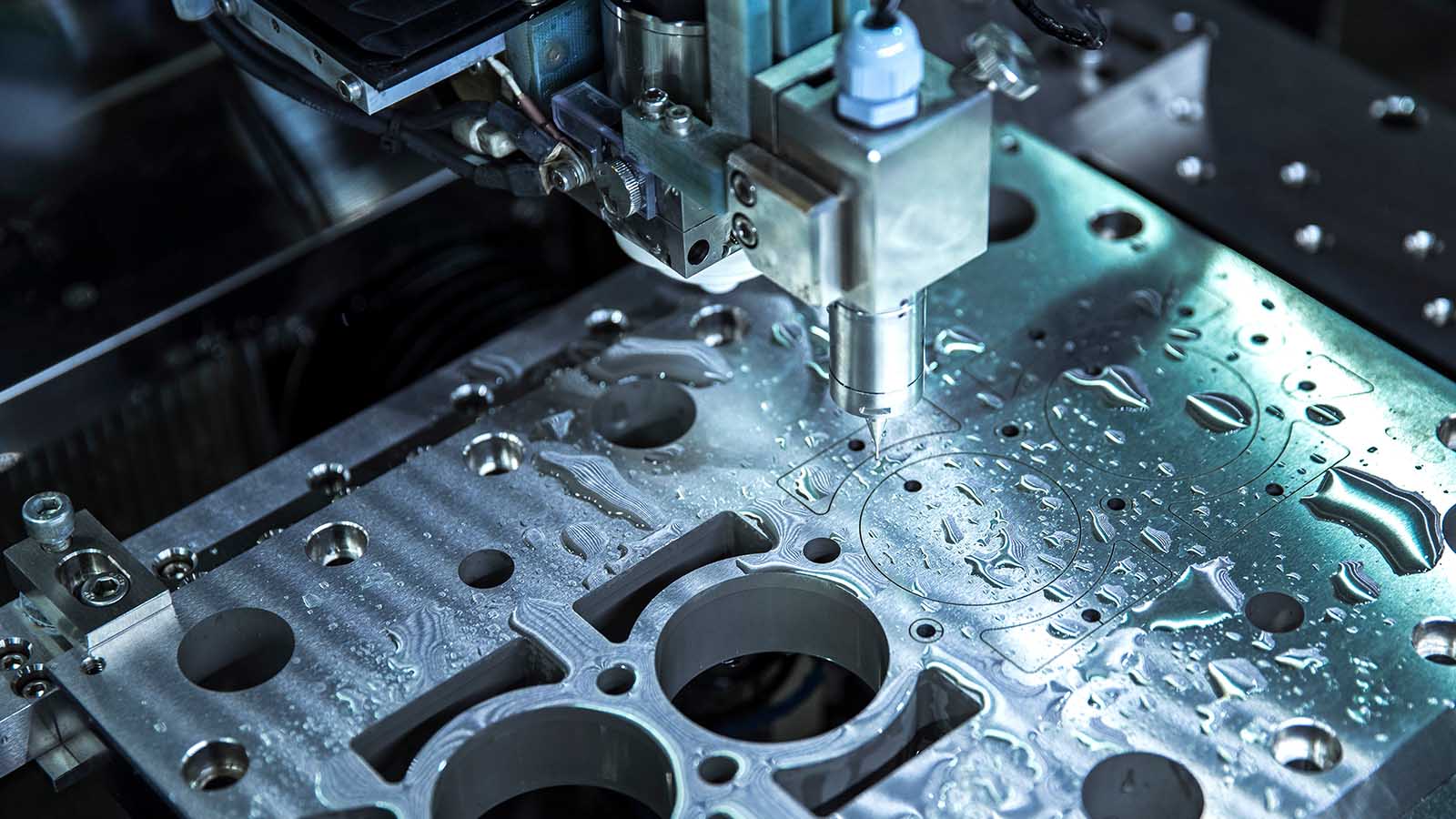

In the heart of Colorado’s aerospace hub, CNC machining has emerged as a critical driving force, propelling technological advancements and innovation within the industry. CNC, which stands for Computer Numerical Control, represents a transformative leap in the way precision components are manufactured. This technology allows for unparalleled accuracy and repeatability in the production of intricate aerospace parts.

CNC machining, as its name suggests, relies on computers to control and execute precise machining operations. The combination of computer software and state-of-the-art machinery empowers manufacturers to craft complex components with remarkable consistency and precision. From turbine blades to rocket nozzles, CNC machining plays an indispensable role in shaping the aerospace industry’s future.

The Aerospace Industry’s Reliance on CNC Machining

The aerospace industry demands precision and reliability like no other. From commercial airliners to space exploration missions, the components used must perform flawlessly in the most challenging environments. CNC machining is at the forefront of meeting these stringent requirements.

Complex Geometries: Aerospace components often feature intricate and complex geometries that would be impossible to manufacture without CNC machining. This technology allows for the creation of parts with precision and consistency that traditional methods cannot match.

Materials Diversity: Aerospace applications require the use of a wide range of materials, from lightweight composites to high-strength alloys. CNC machining can handle this diversity, ensuring that components are crafted to withstand the extreme conditions of space, high altitudes, and intense pressures.

Reduced Human Error: Human error can be a costly factor in manufacturing. CNC machining eliminates much of this risk by relying on computer-guided processes, reducing the likelihood of defects and ensuring consistently high-quality results.

Prototyping and Testing: The aerospace industry relies heavily on prototyping and testing to refine designs and ensure safety. CNC machining allows for the rapid production of prototypes, enabling engineers to evaluate and improve designs quickly.

High-Volume Production: For aerospace manufacturers, scalability is crucial. CNC machining can handle high-volume production runs with ease, ensuring that the supply chain can keep up with the industry’s demands.

Strict Regulatory Compliance: Aerospace components must adhere to strict regulatory standards. CNC machining’s precision and consistency make it easier to meet these standards and obtain the necessary certifications.

Preece Machining and Assembly: Your Trusted CNC Machining Partner

When it comes to CNC machining, one name that has consistently stood out as a trusted partner for businesses in the aerospace industry is Preece Machining and Assembly. With a legacy spanning decades, Preece has earned a stellar reputation for delivering precision-engineered components that meet and exceed the rigorous demands of aerospace applications.