Unveiling the Secrets of INVAR Machining: Preece’s Expertise

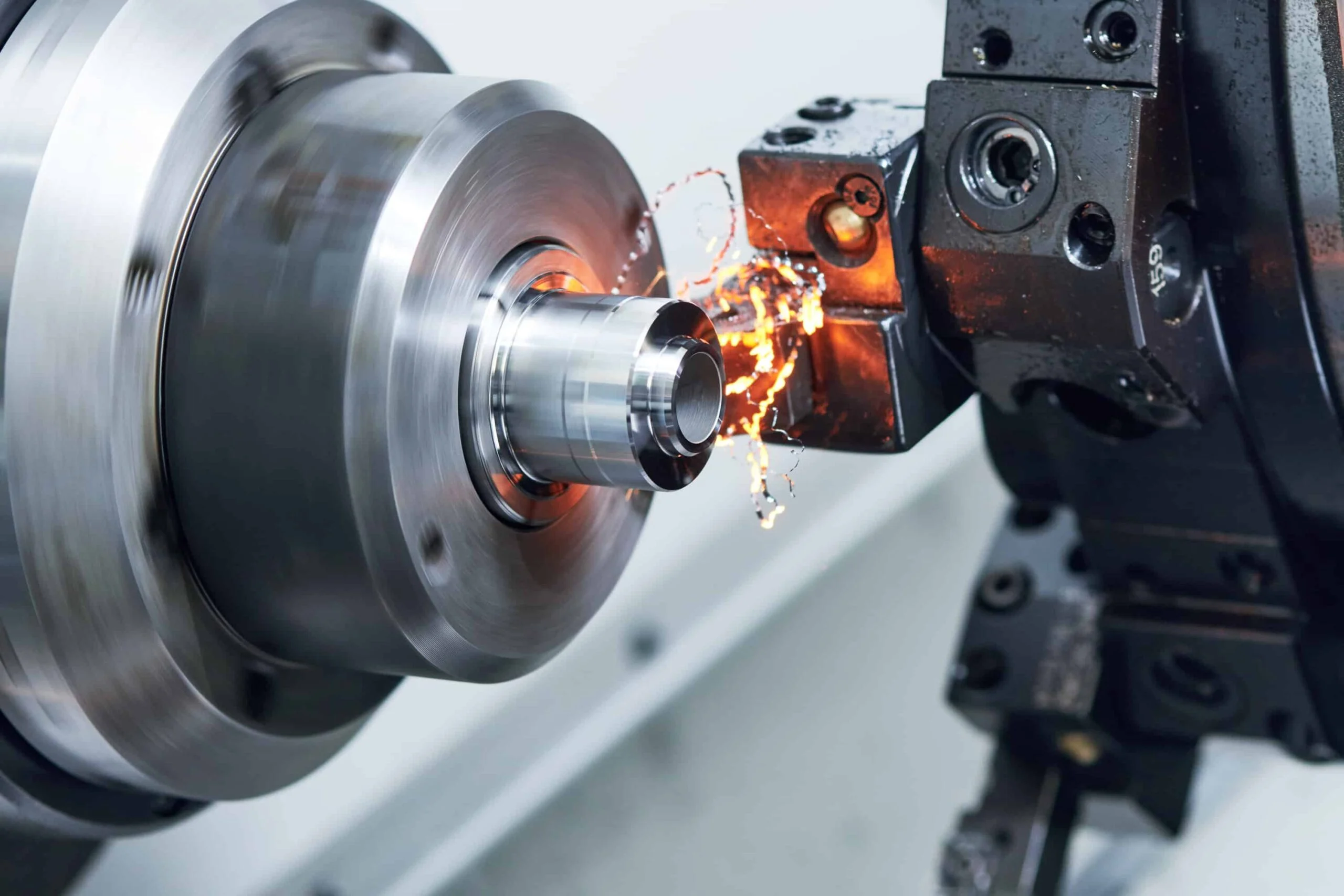

In this blog, we delve deep into the world of INVAR machining, shedding light on the complexities involved and uncovering the remarkable expertise.

The Essence of INVAR Machining

Before we delve deeper into Preece’s expertise, it’s essential to grasp the essence of INVAR machining. INVAR, an abbreviation for Invariable, is aptly named due to its unique property of minimal expansion or contraction over a wide range of temperatures. This characteristic makes INVAR an ideal choice for applications where dimensional stability is critical. However, working with INVAR presents a formidable challenge for manufacturers due to its low machinability compared to other metals.

The Challenges of INVAR Machining

INVAR machining presents several challenges that require meticulous attention to detail and specialized equipment. Here are some of the key obstacles:

- Thermal Sensitivity: As mentioned earlier, INVAR is extremely sensitive to temperature changes. During machining, the heat generated can cause the material to expand or contract, leading to dimensional inaccuracies. Controlling the temperature and minimizing thermal stress is crucial to maintain precision.

- Tool Wear: INVAR is known to be abrasive and can cause rapid tool wear. This necessitates the use of high-quality, durable cutting tools and constant monitoring to ensure the machining process remains efficient.

- Material Composition: The composition of INVAR can vary slightly, affecting its machinability. Understanding the specific alloy composition is essential to tailor the machining process accordingly.

- Chip Control: Managing chips and ensuring they do not become entangled with the cutting tool is crucial to avoid interruptions and maintain surface quality.

Given these challenges, it becomes evident that INVAR machining is not a task for the faint-hearted. It demands expertise, precision, and state-of-the-art equipment, all of which are embodied in the services offered by Preece Machining and Assembly.

Preece Machining and Assembly: The Masters of INVAR Machining

When it comes to INVAR machining, Preece Machining and Assembly stands out as an industry leader with a proven track record of excellence. With decades of experience and a team of highly skilled engineers and machinists, Preece has earned a reputation for mastering the intricacies of INVAR machining.

- State-of-the-Art Facilities: Preece boasts state-of-the-art machining facilities equipped with the latest technology and precision equipment. This ensures that every component produced meets the highest standards of quality and accuracy. Their commitment to continuous investment in cutting-edge machinery reflects dedication to staying at the forefront of the industry.

- Expertise in Material Science: Understanding the nuances of INVAR’s composition is vital for successful machining. Preece’s team of experts possesses in-depth knowledge of the material’s properties, allowing them to tailor machining processes to the specific alloy being used. This level of expertise ensures that clients receive components that meet exact specifications.

- Temperature Control: Managing thermal sensitivity is a hallmark of Preece’s INVAR machining expertise. They employ advanced techniques and tooling that minimize the impact of heat on the material, resulting in components that maintain dimensional stability even in extreme temperature environments.

- Precision and Quality Assurance: Preece’s commitment to precision and quality is unwavering. They employ rigorous quality control measures at every stage of the machining process, ensuring that each component undergoes thorough inspection and testing before leaving facility. This dedication to quality has earned them the trust of clients across various industries, from aerospace to scientific research.

- Customized Solutions: Preece understands that every project is unique, and approach to INVAR machining is never one-size-fits-all. They work closely with clients to develop customized solutions that meet specific requirements, whether it’s for aerospace components, optical instruments, or any other application that demands precision and stability.

The Preece Advantage

Choosing Preece Machining and Assembly for your INVAR machining needs offers several distinct advantages:

- Precision and Quality: Preece’s commitment to precision and quality ensures that you receive components that meet the highest standards, delivering reliability and performance.

- Expertise: Our team’s expertise in INVAR machining sets them apart, allowing them to tackle even the most challenging projects with confidence and precision.

- Customization: Preece’s ability to tailor machining processes to the unique requirements of each project means that you get components that are designed to perform optimally in your specific application.

- Cost-Efficiency: By minimizing material wastage and maximizing efficiency, Preece helps you achieve cost-effective solutions without compromising on quality.

- Timely Delivery: They understand the importance of meeting deadlines, and efficient processes ensure timely delivery of your components.

Why Choose Preece Machining and Assembly for INVAR Machining?

- Proven Track Record: Preece has a long history of successful INVAR machining projects, with a portfolio that includes components for the aerospace industry, scientific instruments, and more. Our track record speaks volumes about expertise.

- Cutting-Edge Technology: Preece stays at the forefront of machining technology, constantly updating equipment and techniques to ensure the highest quality results.

- Custom Solutions: Every project is unique, and Preece understands this. They work closely with clients to tailor machining processes to specific requirements, ensuring the best possible outcome.

- Quality Assurance: Preece is committed to delivering excellence in every component they produce. Rigorous quality control measures are in place to guarantee that every piece meets the strictest standards.

- Competitive Pricing: Despite exceptional expertise, Preece offers competitive pricing, making precision INVAR machining accessible to a wide range of industries.