How Prototype Machining Enhances Product Performance in California?

In today’s rapidly evolving technological landscape, the process of bringing a new product to market demands precision, innovation, and efficiency. For businesses in California, a state renowned for its innovation hubs and cutting-edge industries, staying ahead requires embracing every advantage available. This is where prototype machining comes into play. This blog explores the significance of prototype machining in enhancing product performance, particularly in California’s competitive business environment.

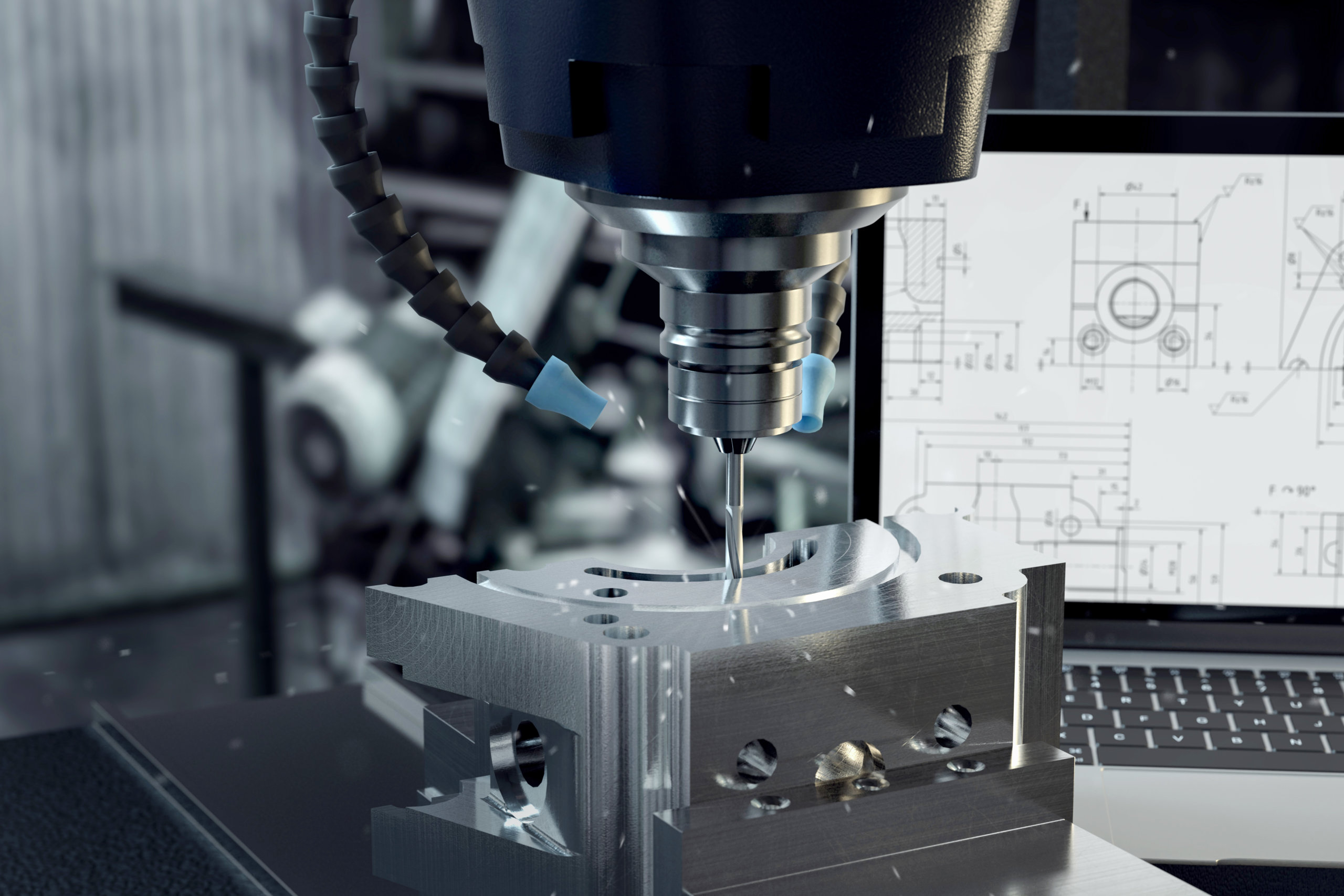

The Essence of Prototype Machining

At the heart of every successful product lies a meticulous process of development, testing, and refinement. This process is exponentially more effective when prototype machining is employed. Prototype machining involves the creation of functional, scaled-down models of a product, allowing designers and engineers to assess its form, function, and manufacturability. The utilization of this technique has revolutionized product development by enabling iterative improvements, reducing risks, and ultimately ensuring a superior end result.

Advantages of Prototype Machining

Accelerated Innovation: In the dynamic realm of California’s industries, innovation is the cornerstone of success. Prototype machining expedites innovation by providing a tangible representation of a concept. This physical manifestation facilitates brainstorming, iteration, and collaboration among teams. As a result, the creative process is streamlined, leading to faster conceptualization and development of groundbreaking products.

Mitigation of Design Flaws: Identifying design flaws before full-scale production is a significant challenge in product development. Prototype machining addresses this challenge by offering a hands-on approach to testing and evaluation. Designers can interact with a physical model, uncovering potential flaws that might not be apparent in digital simulations. This preemptive identification of issues saves valuable time and resources that would otherwise be expended in rectifying problems during later stages of production.

Customization and Adaptation: California’s diverse industries cater to a wide range of needs, often requiring customized solutions. Prototype machining allows for rapid customization and adaptation. Whether it’s fine-tuning dimensions, materials, or functionality, this technique empowers designers to make informed decisions based on real-world prototypes. As a result, products can be tailored to meet specific requirements with precision.

Preece Machining and Assembly: Your Prototype Machining Partner

When it comes to prototype machining in California, one name stands out: Preece Machining and Assembly. With a proven track record of delivering high-quality machining solutions, Preece Machining and Assembly is a reliable partner for businesses aiming to enhance our product development process.

Streamlined Development Workflow

Preece Machining and Assembly offers a comprehensive suite of prototype machining services that seamlessly integrate with a client’s development workflow. Our team of experienced professionals collaborates closely with clients to transform concepts into tangible prototypes, ensuring that every design iteration is accurately translated into a functional model.

Cutting-Edge Technology

Staying true to California’s reputation as a tech hub, Preece Machining and Assembly leverages cutting-edge machining technologies. From computer numerical control (CNC) machining to additive manufacturing processes, we possess the tools and expertise to create prototypes with unparalleled precision and efficiency. This commitment to technological advancement aligns seamlessly with the innovation-driven ethos of businesses in California.

Iterative Refinement

One of the key aspects that sets Preece Machining and Assembly apart is emphasis on iterative refinement. We understand that product development is an evolving process, and each iteration is an opportunity to enhance the final outcome. Through a feedback-driven approach, we facilitate continuous improvements, resulting in prototypes that closely mirror the envisioned end product.