Precision Machining Solutions from Prototype to High Volume

Precision machining plays a pivotal role in this journey, ensuring that the intricate details of each component are meticulously crafted. This blog leaps into the world of precision machining solutions, exploring the significance of prototype machining and the seamless transition to high-volume production.

Understanding the Essence of Prototype Machining

Prototype machining serves as the initial step in the manufacturing process, allowing engineers and designers to test and refine concepts before full-scale production begins. The precision and accuracy of prototype machining are critical, as they lay the foundation for the success of the final product. During this phase, manufacturers can identify potential design flaws, test material compatibility, and make necessary adjustments to enhance functionality.

The Role of Precision Machining in Prototyping

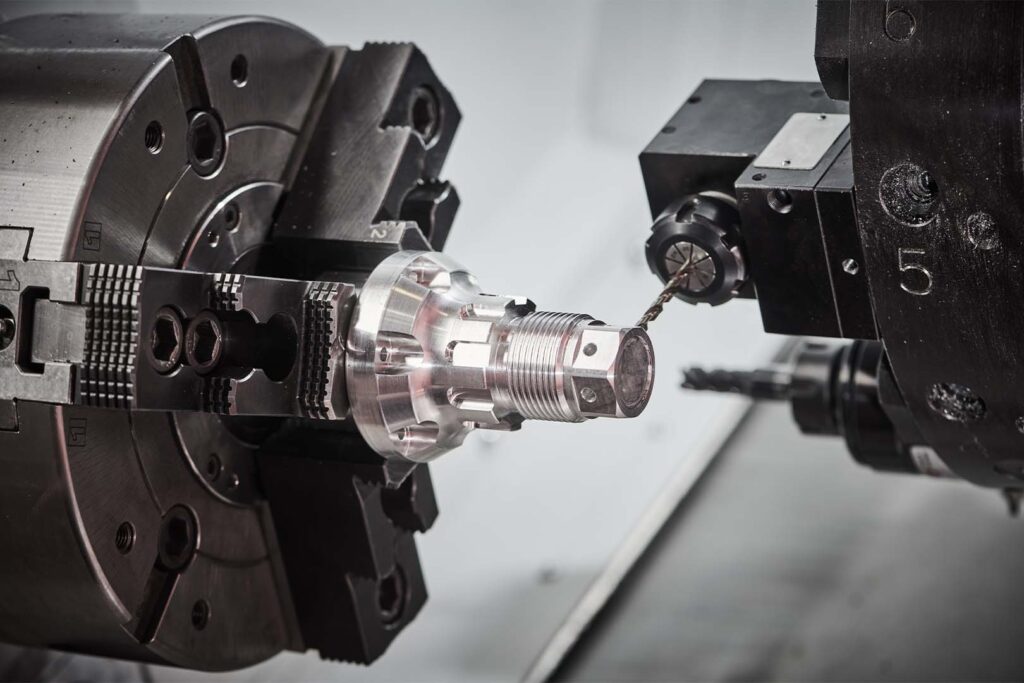

Precision machining techniques, such as CNC (Computer Numerical Control) machining, are instrumental in the creation of prototypes with unparalleled accuracy. CNC machining ensures that each component is manufactured to exact specifications, minimizing deviations and errors. This level of precision is paramount in prototype machining, where even the slightest imperfection can have a cascading effect on the final product.

Benefits of Prototype Machining

Rapid Prototyping for Time Efficiency

One of the key advantages of prototype machining is the ability to rapidly produce prototypes for testing. This quick turnaround time enables manufacturers to accelerate the product development cycle, ultimately reducing time-to-market. For businesses operating in competitive industries, this speed is a crucial factor that can make the difference between success and lagging behind.

Cost-Effective Iterations

Prototype machining allows for cost-effective iterations. By identifying and addressing issues early in the design phase, manufacturers can avoid costly mistakes during mass production. This iterative process not only saves time but also ensures that the final product meets the highest standards of quality.

Transitioning to High-Volume Production

Once the prototype has undergone thorough testing and refinement, the focus shifts towards high-volume production. Precision machining techniques that proved successful during the prototyping phase can now be scaled up to meet the demands of mass production.

Scaling Precision: The CNC Advantage

CNC machining, which played a pivotal role in prototype machining, seamlessly scales up for high-volume production. Its automated processes ensure consistency in manufacturing, producing components with the same precision and accuracy as the initial prototypes. This scalability is essential for meeting the demands of large-scale production without compromising on quality.

Material Selection and Optimization

During the transition to high-volume production, manufacturers must consider material optimization to meet cost-effectiveness and performance requirements. Prototype machining insights allow for informed decisions on material selection, ensuring that the chosen materials are suitable for both the prototype and mass production phases.

Why Choose Preece Machining and Assembly for Prototype Machining?

When it comes to prototype machining, choosing the right partner can make a significant difference. Preece Machining and Assembly stand out as industry leaders, offering comprehensive solutions from prototyping to high-volume production. With state-of-the-art CNC machining capabilities and a team of experienced professionals, Preece Machining and Assembly provide the precision and reliability needed for successful product development.