How Machine and Assembly Enhances Precision in Invar Machining

In the evolving manufacturing world, precision is the keystone upon which industries build their success. Invar, a nickel-iron alloy known for its low coefficient of thermal expansion, has become a stalwart material in applications demanding exacting standards. This article takes a deep dive into the intricate world of Invar machining, exploring how the seamless integration of cutting-edge machines and precision assembly processes is revolutionizing the way we approach the fabrication of components in various industries.

Understanding Invar Machining

Invar’s unique properties make it an ideal choice for applications where dimensional stability is paramount, such as aerospace, optics, and scientific instruments. However, working with this alloy presents challenges due to its hardness and susceptibility to work hardening. Enter Invar machining, a process that demands a marriage of technological prowess and meticulous assembly techniques to achieve the desired precision.

The Role of Advanced Machinery

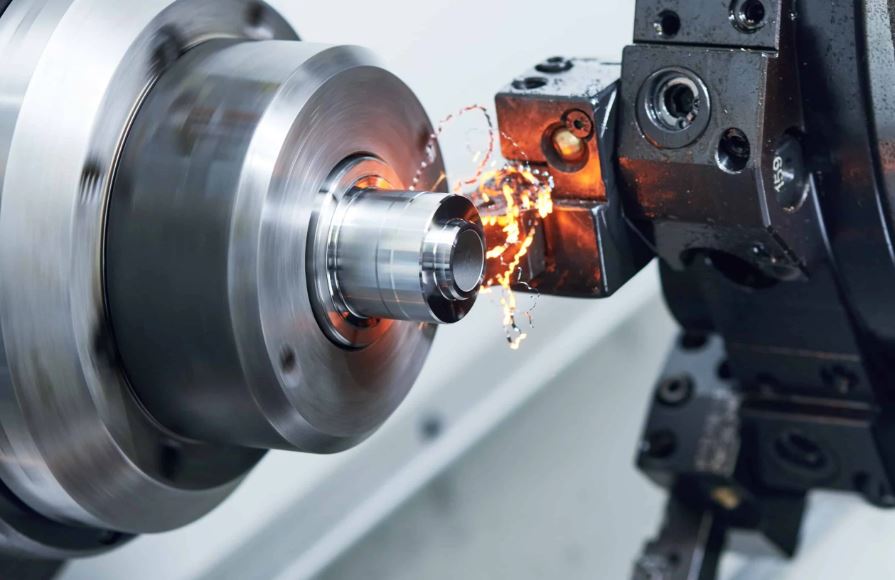

CNC Machining for Unparalleled Accuracy

Computer Numerical Control (CNC) machining has emerged as a game-changer in the realm of Invar fabrication. This technology allows for the creation of intricate and precise components with minimal human intervention. CNC machines excel at executing complex geometries and tight tolerances, making them indispensable in Invar machining. The ability to program these machines with unparalleled precision ensures consistent results, reducing the margin for error inherent in traditional machining methods.

EDM Machining for Intricate Designs

Electrical Discharge Machining (EDM) has become a cornerstone in the precision machining of Invar. This non-traditional method relies on electrical discharges to erode material with pinpoint accuracy. EDM is particularly effective when dealing with intricate designs and features, offering a level of precision that is hard to achieve with conventional machining techniques. The adaptability of EDM makes it an invaluable tool in the arsenal of manufacturers working with Invar.

Precision Assembly Techniques

Thermal Management for Dimensional Stability

One of the primary challenges in Invar machining lies in managing its low coefficient of thermal expansion. Precision assembly techniques involve meticulous thermal management to ensure that the finished components maintain dimensional stability across a wide range of temperatures. This is crucial for applications where changes in size due to temperature variations could compromise the functionality of the end product.

Adhesive Bonding for Seamless Integration

Precision assembly goes beyond the machining stage; it extends to how components are joined together. Adhesive bonding has gained prominence in Invar assembly, providing a method that ensures a seamless and robust integration of parts. This technique not only enhances precision but also contributes to the overall structural integrity of the final product.

Synergy in Action: Machine and Assembly Working in Tandem

The true magic of precision in Invar machining happens when advanced machines and assembly techniques work in tandem. CNC machines create intricate components with microscopic precision, and precision assembly ensures these components come together seamlessly. The result is a finished product that meets and often exceeds the stringent requirements of industries relying on Invar for their critical applications.

Challenges and Innovations

As with any technological advancement, challenges persist. The hardness of Invar poses tool wear issues in machining processes, requiring continuous innovation in tool materials and coatings. Additionally, addressing the intricate thermal considerations demands a comprehensive approach that integrates machining and assembly seamlessly. Manufacturers are continually pushing the boundaries of innovation to overcome these challenges and unlock new frontiers in precision.

Final Thoughts

Invar machining is not just a process; it’s a symphony of technological marvels orchestrated to achieve precision at the micro and macro levels. The combination of advanced machines and meticulous assembly techniques is propelling industries forward, allowing them to push the boundaries of what is possible. As we stand at the crossroads of technological innovation, the synergy of Machine and Assembly in Invar machining is carving out a path towards a future where precision knows no bounds.