Strategies for Success in High Volume Production Machining

Driving Success in High Volume Production Machining

In the ever-evolving landscape of manufacturing, the pursuit of efficiency is relentless, especially in the realm of high volume production machining. To emerge victorious in this fiercely competitive arena, companies must deploy an extensive array of strategies carefully crafted to optimize every aspect of their machining processes. In this guide, we take an in-depth look of high volume production machining strategies aimed at not just achieving success, but dominating the market with unparalleled prowess and precision.

Understanding the Essence of High Volume Production Machining

At its core, high volume production machining represents the epitome of mass manufacturing efficiency. It involves the swift and consistent fabrication of large quantities of machined components to meet the demands of industries such as automotive, aerospace, electronics, and consumer goods. This process serves as the lifeblood of modern manufacturing, enabling companies to achieve economies of scale and maintain a competitive edge in the global marketplace.

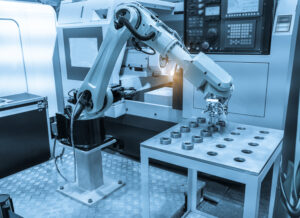

Embracing Automation: A Cornerstone of Efficiency and Precision

Automation stands as the bedrock upon which successful high volume production machining is built. By integrating sophisticated automated systems into their operations, manufacturers can unlock unprecedented levels of efficiency, consistency, and cost-effectiveness. Automated machinery operates tirelessly, executing tasks with impeccable precision and remarkable speed, thereby ensuring seamless production flows even when dealing with staggering volumes of components.

Lean Manufacturing: Streamlining Processes for Optimal Performance

In the quest for operational excellence, lean manufacturing principles emerge as indispensable guides. These principles, rooted in the philosophy of waste reduction, continuous improvement, and value maximization, provide a framework for streamlining high volume production machining processes. Through meticulous analysis of workflows and relentless pursuit of efficiency gains, manufacturers can eliminate waste, minimize downtime, and enhance overall productivity, thus paving the way for sustained success.

Harnessing Cutting-Edge Machining Technologies

Staying ahead of the curve in high volume production machining necessitates a relentless pursuit of technological innovation. From Computer Numerical Control (CNC) machining to robotic automation and additive manufacturing, these cutting-edge technologies offer unprecedented capabilities in terms of speed, accuracy, and versatility. By investing in state-of-the-art equipment and staying abreast of emerging trends, manufacturers can meet evolving customer demands and maintain a competitive edge in the dynamic landscape of modern manufacturing.

Ensuring Uncompromising Quality at Every Stage

Quality is the cornerstone of customer satisfaction and long-term success in high volume production machining. Rigorous quality assurance measures, including comprehensive inspections, stringent adherence to specifications, and adherence to regulatory requirements, are essential to uphold the reputation of both the manufacturer and the end product. By prioritizing quality at every stage of the production process, companies can instill confidence in their customers and establish themselves as trusted leaders in their respective industries.

Optimizing Workflow Planning and Scheduling

Efficient workflow planning and scheduling are critical components of high volume production machining success. Leveraging advanced planning software, predictive analytics, and real-time monitoring tools enables manufacturers to create optimized production schedules, minimize lead times, and proactively identify and address potential bottlenecks. This strategic approach not only enhances agility and responsiveness but also ensures optimal resource utilization and operational efficiency, thereby maximizing throughput and profitability.

Investing in Human Capital: Training and Development

The value of a skilled and knowledgeable workforce cannot be overstated in high volume production machining. Investing in comprehensive training programs, ongoing skills development initiatives, and safety training empowers employees to operate machinery proficiently, troubleshoot issues effectively, and prioritize safety protocols. By nurturing talent and fostering a culture of continuous learning and development, manufacturers can cultivate a dynamic and adaptable workforce capable of driving innovation, problem-solving, and sustaining long-term success.

Building Resilience in the Supply Chain

A robust and resilient supply chain is essential for maintaining operational continuity and mitigating risks in high volume production machining. Close collaboration with suppliers, diversification of sourcing strategies, and proactive risk management measures are crucial for mitigating potential disruptions such as material shortages, logistics challenges, or geopolitical uncertainties. By prioritizing supply chain resilience and agility, manufacturers can ensure uninterrupted production and meet customer demands even in the face of unforeseen challenges.

Championing Sustainability: A Moral and Strategic Imperative

In an era marked by growing environmental awareness and regulatory scrutiny, sustainability has emerged as a fundamental business imperative. High volume production machining operations can have significant environmental impacts, from energy consumption to waste generation. By embracing sustainable practices such as recycling, energy efficiency, and the use of eco-friendly materials, manufacturers can minimize their ecological footprint, reduce operational costs, and enhance their brand reputation, thus future-proofing their operations and positioning themselves as responsible corporate citizens in the eyes of customers, investors, and regulators alike.

Cultivating a Culture of Continuous Improvement

Continuous improvement is not merely a goal but a way of life in high volume production machining. Encouraging employee involvement, fostering a culture of innovation, and embracing a mindset of continual learning and development enable manufacturers to identify opportunities for optimization, drive process improvements, and stay ahead of the competition. By empowering employees to contribute ideas, experiment with new technologies, and implement best practices, companies can create a culture of excellence that permeates every aspect of their operations, driving sustained growth, innovation, and competitive advantage.

Concluding Thoughts: Driving Success Through Strategic Excellence

Success in high volume production machining demands more than just technical prowess—it requires a holistic and strategic approach that encompasses automation, lean principles, technological innovation, quality assurance, efficient planning, talent development, supply chain resilience, sustainability, and a relentless commitment to continuous improvement. By embracing these strategies and weaving them into the fabric of their organizational culture, companies can optimize their operations, maximize efficiency, and achieve sustainable growth in the fiercely competitive landscape of modern manufacturing. At Machine & Assembly, we advocate for the adoption of these strategies to unlock the full potential of high volume production machining and propel your business towards enduring success.