Why High Volume Machining is Crucial for Efficient Production in Colorado?

In a world where efficiency and productivity are the cornerstones of success, industries are constantly searching for ways to optimize processes. One key solution that has gained prominence in Colorado’s manufacturing landscape is high volume machining. This innovative approach to production brings with it a host of benefits that can significantly enhance a company’s operational prowess. This blog delves into the realm of high volume machining and explains why it is a crucial factor for efficient production in Colorado.

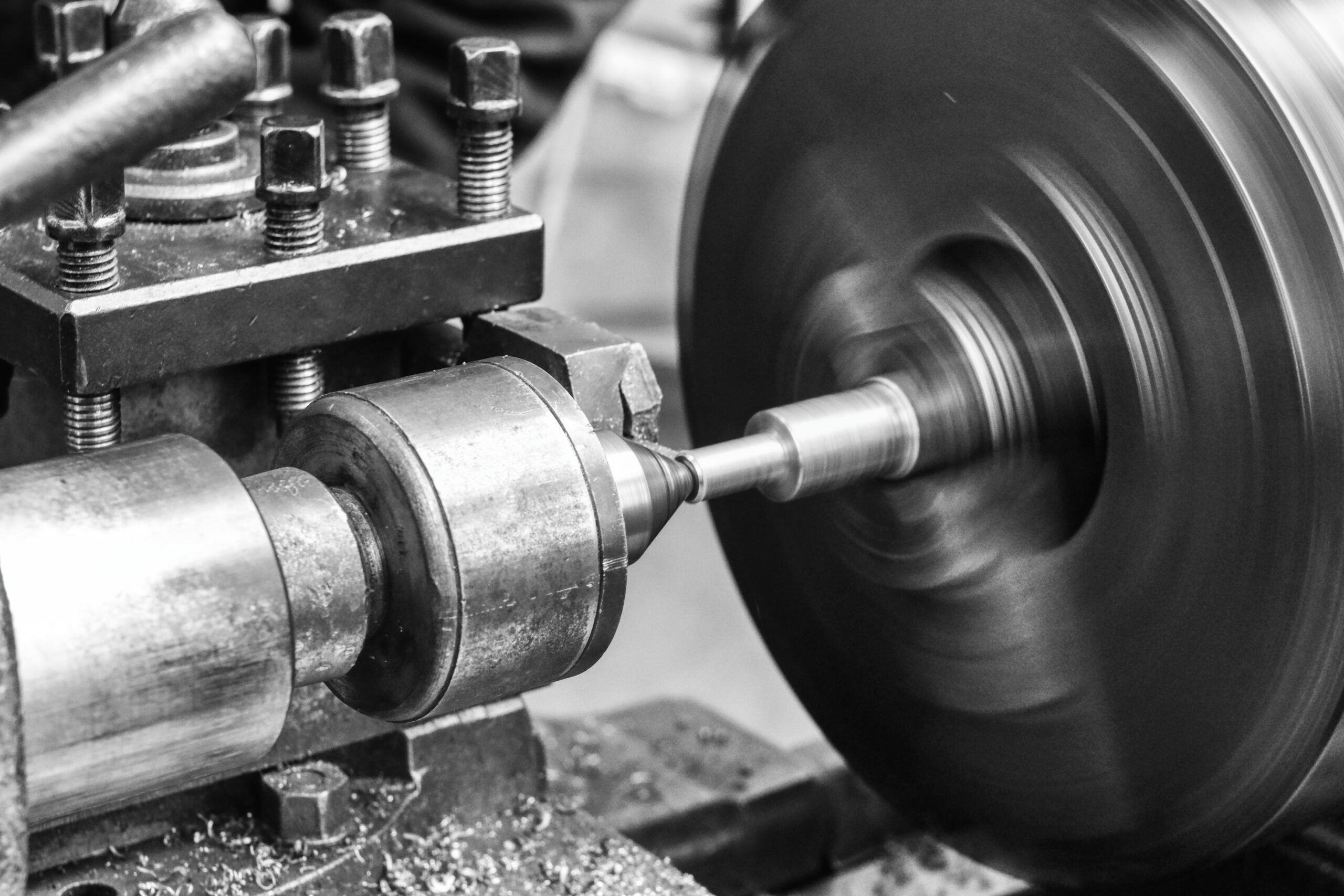

High Volume Machining

High volume machining refers to a manufacturing technique that involves the rapid and continuous production of large quantities of parts or components using advanced machining equipment. This approach is particularly well-suited for industries that demand a significant output of standardized parts, such as automotive, aerospace, electronics, and more. By leveraging automation, precision tools, and streamlined processes, high volume machining optimizes production lines for maximum efficiency.

The Role of High Volume Machining in Colorado’s Industries

In Colorado, a state known for its diverse industrial landscape, high volume machining plays a pivotal role in driving efficient production. From the bustling cities to the quieter rural areas, numerous industries benefit from the advantages this method offers. In sectors like automotive manufacturing, where the demand for standardized parts like engine components and chassis elements is constant, high volume machining ensures a steady supply to meet market needs. This allows companies to not only fulfill orders promptly but also maintain a competitive edge in the industry.

Advantages of High Volume Machining

Speed and Consistency: High volume machining excels in delivering consistent, precise results at a rapid pace. Automated processes and optimized tooling significantly reduce production time, enabling companies to fulfill large orders in shorter timeframes without compromising quality.

Cost-Effectiveness: When producing in bulk, economies of scale come into play. High volume machining allows manufacturers to reduce per-unit production costs, leading to higher profit margins. Additionally, the reduced need for manual intervention lowers labor costs, making it an economically viable solution.

Enhanced Quality Control: Modern high volume machining systems incorporate advanced sensors and monitoring technology, ensuring that each part produced adheres to the specified standards. This tight quality control minimizes defects and the likelihood of recalls, bolstering a company’s reputation for reliability.

Resource Optimization: High volume machining optimizes material usage, minimizing waste and conserving resources. This eco-friendly approach resonates well with environmentally conscious consumers and meets regulatory requirements.

Scalability: As businesses grow, so does the demand for products. High volume machining provides the flexibility to scale up production without compromising on quality, ensuring that companies can seize new opportunities without hesitation.

Choosing the Right Partner: Preece Machining and Assembly for High Volume Machining

While the benefits of high volume machining are undeniable, it’s essential to partner with the right machining service provider to fully harness its potential. In Colorado, one name stands out in this domain – Preece Machining and Assembly. With a proven track record of delivering high-quality machining solutions, we have become synonymous with efficiency, precision, and reliability.

Preece Machining and Assembly expertise in high volume machining is a result of state-of-the-art facilities and a team of skilled professionals who understand the intricacies of modern manufacturing. By utilizing the latest CNC (Computer Numerical Control) technology, we ensure that every part produced meets the exact specifications, down to the micron. This dedication to precision is what sets them apart in the competitive landscape of machining services.

Additionally, Preece Machining and Assembly commitment to continuous improvement means that we stay updated with the latest advancements in machining techniques. This enables them to offer innovative solutions that further enhance the efficiency of the production process. Whether it’s reducing cycle times, minimizing tool wear, or optimizing material utilization, expertise covers the entire spectrum of high volume machining advantages.