AS9100 Certification: What It Means for Preece Machining

In this article, we delve into the world of AS9100 Certification, its significance for Preece Machining, and why they deserve your consideration as a partner for aerospace and machining needs.

AS9100: Unpacking the Standard

Before we delve into the implications of AS9100 Certification for Preece Machining, let’s understand what AS9100 all is about. AS9100 is a globally recognized quality management system standard specifically designed for the aerospace industry. It encompasses and builds upon the requirements of ISO 9001, the widely acknowledged standard for quality management systems. AS9100 adds aerospace-specific requirements and focuses on factors critical to the aviation, space, and defense industries.

AS9100 in a Nutshell

AS9100 places rigorous demands on organizations seeking certification. It covers various aspects of operations, including:

Quality Control: AS9100 necessitates meticulous quality control measures. Every facet of production, from design and development to manufacturing and testing, must meet the highest standards.

Risk Management: Safety is paramount in aerospace, and AS9100 requires companies to have robust risk management systems in place to identify and mitigate potential hazards.

Documented Processes: Detailed documentation is a cornerstone of AS9100. Companies must maintain extensive records of their processes, ensuring transparency and traceability.

Supplier Management: AS9100 mandates that companies establish stringent criteria for selecting and monitoring suppliers to maintain consistent quality throughout the supply chain.

Continuous Improvement: A commitment to continuous improvement is ingrained in AS9100. Organizations must constantly assess and enhance their processes and systems.

Preece Machining’s AS9100 Certification Journey

For Preece Machining and Assembly, achieving AS9100 Certification was not merely a box to tick but a strategic decision to enhance their offerings and demonstrate their unwavering commitment to quality and precision. Their journey to AS9100 Certification was marked by dedication, hard work, and an unyielding focus on excellence.

· Meeting Stringent Standards

One of the most challenging aspects of AS9100 Certification is meeting its stringent standards. Preece Machining had to revamp its processes, from procurement to production, to ensure compliance with AS9100 requirements. This involved a meticulous review and enhancement of quality control measures, risk management protocols, and documentation procedures.

· Investment in Training and Technology

To align with AS9100, Preece Machining invested significantly in training its workforce and upgrading its technology. This investment not only ensured that their employees were well-equipped to meet the new standards but also improved efficiency and precision in their machining processes.

· Enhanced Supplier Relationships

AS9100 places a strong emphasis on supplier management. Preece Machining engaged in a comprehensive review of its supplier base, ensuring that all partners met the stringent requirements. Strengthened supplier relationships have contributed to the consistent quality of their products.

Benefits of AS9100 Certification for Preece Machining

Having successfully obtained AS9100 Certification, Preece Machining now stands at the forefront of the aerospace machining industry. This certification brings a plethora of benefits to both the company and its clients.

· Unparalleled Quality

AS9100 Certification signifies a commitment to unparalleled quality. Preece Machining’s adherence to the standard guarantees that their products and services meet or exceed the exacting requirements of the aerospace industry. When you partner with them, you can trust that you’re getting the highest quality components for your aerospace projects.

· Enhanced Safety

Safety is paramount in the aerospace sector. AS9100 Certification ensures that Preece Machining has robust risk management systems in place to identify and mitigate potential hazards. This commitment to safety extends to their products, ensuring that they are reliable and safe for use in critical aerospace applications.

· Reliable Documentation

With AS9100 Certification, you can expect meticulous documentation from Preece Machining. Every step of their manufacturing process is rigorously documented, ensuring transparency and traceability. This not only enhances quality but also provides a valuable resource for auditing and compliance purposes.

· On-Time Delivery

Aerospace projects often operate on tight schedules. Preece Machining’s adherence to AS9100 standards enhances their efficiency and helps ensure on-time delivery of components and assemblies. This reliability is a significant advantage for clients with time-sensitive projects.

· Cost Efficiency

While achieving AS9100 Certification requires investment, it ultimately leads to cost efficiencies in the long run. Improved processes and reduced defects result in lower production costs, which can be passed on to clients in the form of competitive pricing.

Why Choose Preece Machining and Assembly for AS9100 Certification?

If you’re in the aerospace industry and require components or assemblies that meet AS9100 standards, choosing the right partner is crucial. Preece Machining and Assembly offers several compelling reasons why they should be your go-to choice:

· Proven Expertise

Preece Machining’s successful AS9100 Certification is a testament to their expertise and commitment to quality. With years of experience in the aerospace and machining sectors, they have the knowledge and skills to deliver components that meet the most demanding specifications.

· Cutting-Edge Technology

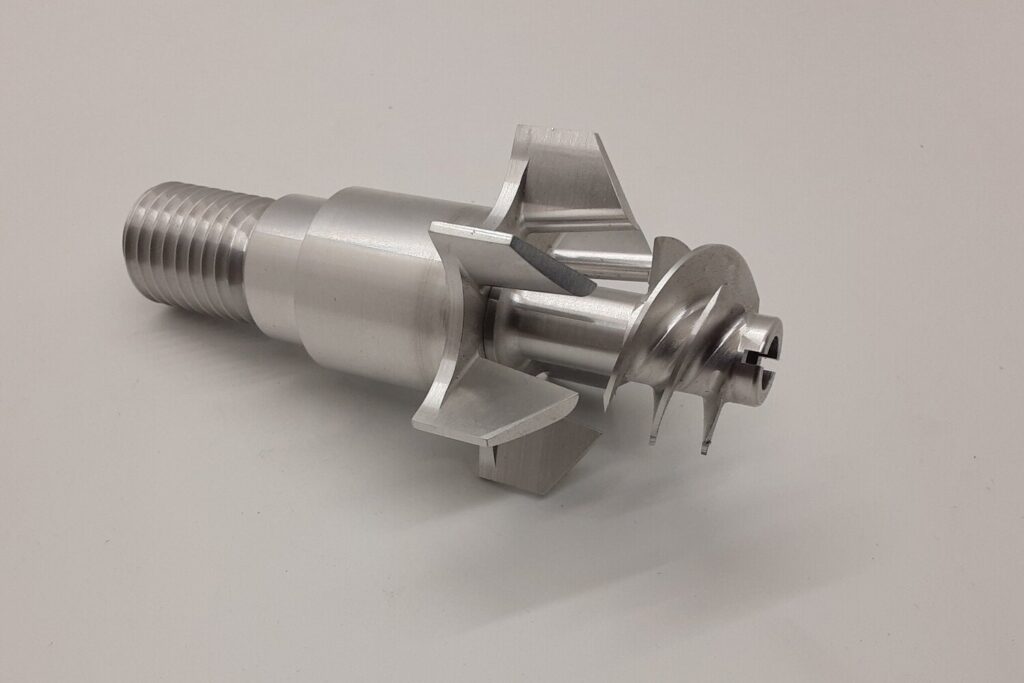

Preece Machining continually invests in cutting-edge technology to ensure precision and efficiency in their manufacturing processes. This commitment to staying at the forefront of technology means you’ll benefit from the latest advancements in aerospace machining.

· Comprehensive Service

Preece Machining doesn’t just stop at machining. They offer a comprehensive service, from design and development to manufacturing and assembly. This end-to-end approach streamlines the production process and ensures seamless integration of components into your aerospace projects.

· Proven Track Record

Preece Machining has a proven track record of delivering high-quality components to some of the most demanding clients in the aerospace industry. Our history of successful projects and satisfied customers speaks volumes about capabilities.

· Commitment to Excellence

AS9100 Certification is a symbol of Preece Machining’s unwavering commitment to excellence. When you choose them as your partner, you’re aligning yourself with a company dedicated to the highest standards of quality and safety.